Whether you need to fill an entire warehouse with massaranduba decking or a showroom with our massaranduba deck tile we can make it happen. We can ship wholesale container loads of our massaranduba lumber products worldwide, When Brazilian hardwoods are your need, Advantage Florestal is your answer. Right here in Belem, we are striving to become the very best. That means complying with FSC certification regulations while never forgetting about quality. With our wide variety of products, incredible staff, and impressive results, we are ready to help you set the standard in your region. Please, don’t hesitate to ask for one of our wholesale representatives and let us know what we can do for you.

Whether you need to fill an entire warehouse with massaranduba decking or a showroom with our massaranduba deck tile we can make it happen. We can ship wholesale container loads of our massaranduba lumber products worldwide, When Brazilian hardwoods are your need, Advantage Florestal is your answer. Right here in Belem, we are striving to become the very best. That means complying with FSC certification regulations while never forgetting about quality. With our wide variety of products, incredible staff, and impressive results, we are ready to help you set the standard in your region. Please, don’t hesitate to ask for one of our wholesale representatives and let us know what we can do for you.

Advantage Florestal Blog – FSC Certified hardwood lumber products

Longleaf Pine Wood Slabs – FSC certified available

Common Name: | Longleaf Pine |

Botanical Name: | Pinus Palustris |

Indigenous to: | Southeastern United States |

Modulus of Rupture: | 14,500 lbf/in2 (100.0 MPa) |

Shrinkage: | Radial: 5.1%, Tangential: 7.5%, Volumetric: 12.2%, T/R Ratio: 1.5 |

How is it dried: | Info coming soon |

Is it dried quickly: | Info coming soon |

Stability: | Info coming soon |

Exterior Wood Recommendation: | Info coming soon |

Fastening Method: | Info coming soon |

Ecosystem impact: | Info coming soon |

Toxicity and allergic reactions: | Info coming soon |

Odor: | Info coming soon |

Product we manufacture using this species: | Info coming soon |

Other common uses: | Info coming soon |

Susceptibility to | |

Dry Wood borers: | Info Coming Soon |

Fungi: | Info Coming Soon |

Termites: | Info Coming Soon |

Treatability: | Info Coming Soon |

Janka Hardness: |

Cuban Laurel Wood Slabs – FSC® Certified is also available

Common Name: | Banyan, Chinese banyan, Malayan banyan, Taiwan banyan, Indian laurel, Curtain Fig, or gajumar, Cuban laurel |

Botanical Name: | Ficus benghalensis |

Indigenous to: | Asia-through out the forest tracts of India, both in sub-Himalayan region and in deciduous forests of Deccan and other parts of South India but frequently cultivated elsewhere in the tropics. |

Modulus of Rupture: | 14,710 lbf/in2 (101.4 MPa) |

Shrinkage: | Radial: 4.8%, Tangential: 7.4%, Volumetric: 13.2%, T/R Ratio: 1.5 |

How is it dried: | Info coming soon |

Is it dried quickly: | Dries easily, liable to warp |

Stability: | |

Exterior Wood Recommendation: | Perishable. Timber is not durable in exposed condition but quite durable in dry places and under cover. |

Fastening Method: | |

Ecosystem impact: | This wood species is not listed in the CITES Appendices or on the IUCN Red List of Threatened Species. |

Toxicity and allergic reactions: | The latex of various species of Ficus can cause allergic skin reactions and contact with the eyes should be avoided. |

Odor: | No characteristic odor. |

Product we manufacture using this species: | Wood Slabs |

Other common uses: | Boxes Building poles Carpentry/joinery (exterior/interior) Cases Containers Furniture Posts Pulp Roundwood |

Susceptibility to | |

Dry Wood borers: | Info Coming Soon |

Fungi: | Info Coming Soon |

Termites: | Info Coming Soon |

Treatability: | Easy |

Janka Hardness: |

Beefwood wood slabs – FSC® Certified is also available

Common Name: | Beefwood, Western Beefwood, Beef Oak, Beef Silky Oak and Silvery Honeysuckle, Australian Pine, She-Oak |

Botanical Name: | Casuarina Spp |

Indigenous to: | Western Australia |

Modulus of Rupture: | 13,630 lbf/in2 (94.0 MPa) |

Shrinkage: | Radial: 3.5%, Tangential: 5.8%, Volumetric: 9.3%, T/R Ratio: 1.7 |

How is it dried: | Info coming soon |

Is it dried quickly: | Info coming soon |

Stability: | Info coming soon |

Exterior Wood Recommendation: | Info coming soon |

Fastening Method: | Info coming soon |

Ecosystem impact: | This wood species is not listed in the CITES Appendices or on the IUCN Red List of Threatened Species. |

Toxicity and allergic reactions: | though there have been no adverse health effects directly attributed to Beefwood, the closely related Southern Silky Oak has been reported to cause eye and skin irritation. |

Odor: | No odor |

Product we manufacture using this species: | live edge wood slabs |

Other common uses: | Inlay, marquetry, turned objects, and other small specialty items. |

Susceptibility to | |

Dry Wood borers: | Info Coming Soon |

Fungi: | Info Coming Soon |

Termites: | Info Coming Soon |

Treatability: | Info Coming Soon |

Janka Hardness: |

Norfolk Island Pine wood slabs – FSC certified available

Common Name: | Norfolk Island Pine, Star pine, Triangle tree, Living Christmas tree |

Botanical Name: | Araucaria heterophylla |

Indigenous to: | Norfolk Island |

Modulus of Rupture: | 11,730 lbf/in2 (80.9 MPa) |

Shrinkage: | Info coming soon |

How is it dried: | Info coming soon |

Is it dried quickly: | Info coming soon |

Stability: | Info coming soon |

Exterior Wood Recommendation: | Info coming soon |

Fastening Method: | Info coming soon |

Ecosystem impact: | This wood species is not listed in the CITES Appendices, but is on the IUCN Red List. It is listed as vulnerable due to a very restricted area of occupancy and/or number of locations. |

Toxicity and allergic reactions: | Info coming soon |

Odor: | Info coming soon |

Product we manufacture using this species: | Info coming soon |

Other common uses: | Info coming soon |

Susceptibility to | |

Dry Wood borers: | Info Coming Soon |

Fungi: | Info Coming Soon |

Termites: | Info Coming Soon |

Treatability: | Info Coming Soon |

Janka Hardness: |

More Product Information

Creating a basket weave frame for cross ventilation

Basket weave carpentry technique that can assist and providing maximum airflow to a deck with limited airflow or clearance. Building a basket weave frame underneath your exotic hardwood deck to provide cross ventilation to prevent common deck issues.

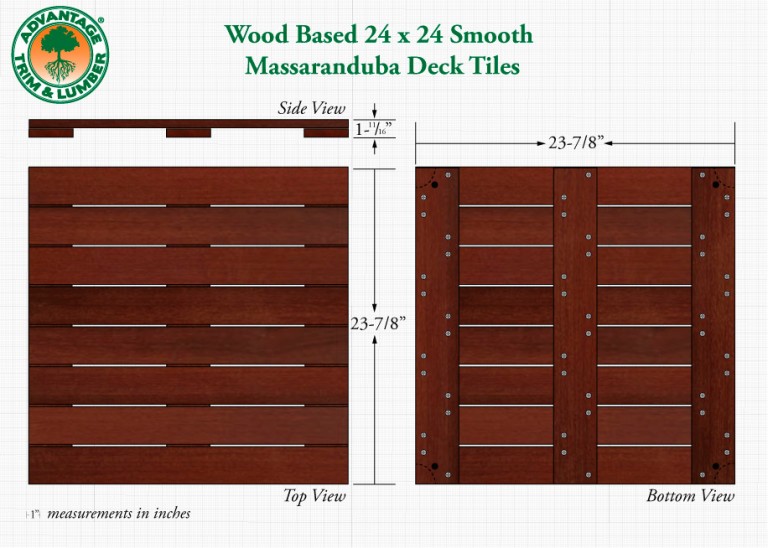

Deck Tile Production at our wholesale FSC Certified mill in Belem Brazil

Advantage Florestal Hardwood Deck Tiles

Our Real Wood Deck Tiles are inexpensive and easy-to-install.

A sneak peek into our deck tile production lines at our FSC certified Brazil Mill.

Our deck tiles are also often called interlocking wood tiles, elevated decking, wood tiles, decking tiles. Regardless of what you call them they make a beautiful addition to your outdoor living space. We manufacture our deck tiles from a variety of species and manufacture them at our wholesale Brazilian mill. Since we are the saw mill, deck tile manufacturer, direct distributor, and exporter. We can offer you direct from the mill wholesale pricing on bulk orders. Our FSC Certified Brazilian mill has the capacity to fill your order and our international logistics team has the experience and knowledge to get it there.

- Advantage Deck Tiles give you, An attractive, dynamic looking surface

- An easy-to-install deck that takes hours, not days

- All the durability & resilience of long-length hardwood decking

- A solid solution to renovating concrete decks & patios

- Years of hassle-free use without any required maintenance

- Built using all stainless steel hardware

Many of our customers prefer to install Advantage Deck Tiles over cracked concrete patios. As you can see from the gallery below, doing so will give you an eyesore you no longer have to live with! Why Advantage Deck Tiles™ are Perfect for DIY Projects

The Deck Tile Difference

Not all deck tiles are created equal.

Assuming two things are equal in quality because they look similar can be a catastrophic mistake. There are many products out there in the world claiming to be of equal quality at a lesser price. Unfortunately, It is clear that the similarities stop at looks, after the product fails. Some companies spend more time mimicking quality than creating it. The reason for this is simple, cheaper labor which leads to a cheaper product. Companies that do this are focused on short term clients who want to spend the least money possible. Advantage Florestal marches to a different beat. We like to think of ourselves as trend setters instead of followers. One trend we will never follow, is making an inferior product to try to save some money. Value is so much more important than cost. We produce value, so you can do the same for your customers. Some of the little differences in deck tiles aren’t so small after time, let’s take a deeper look at why.

Little things – BIG difference

We put a lot of thought and effort into how we build our tiles, not least of which is the way we fasten them. With our “z-back” system we create a stronger tile by providing shear strength and making sure the tile can never come out of square. When only 2 nailers (or even if there is 3 but only run parallel to each other) the only thing holding the tile square is screws. When a tile comes out of square, then getting the installation right is near impossible without going through all of the tiles. The call backs and returns alone could easily cost more than any savings by going with an inferior deck tile. High quality screws are a must. We use a #8 Posidrive, bugle head, chipboard thread, 305 SS screw. There isn’t a higher quality screw for the application. Not to mention the fact every screw is counter sunk. This way it is guaranteed that a screw head won’t be sticking up and scratching the other tiles in shipment. It also guarantees the tile will sit flat when installed without having to double check every tile. We put 2 screws in a diagonal pattern on each side nailer to make sure all the stress is put in the same grain run. This prevents any future checking. Every cross cut is end sealed with wax to maintain moisture content consistency (this also prevents checking and cracking). The “z-back” also has a screw in the center of every board to prevent any bows or twists. There is also a hole (in the bottom only) in every corner that fits the Deckwise tile connectors along with a groove that fits the Deckwise pedestal system. This is all done in our jigs and repeatedly done for consistency in quality. Each tile is checked over to make sure it passes the visual grade before it ever makes its way towards shipment. If you want to take it one step further and get the best of the best Advantage Deck Tiles… We have them available in FSC as well.

The Advantage of Advantage Deck Tiles

Simply said, no one can provide the tile we do at the same value we do. We encourage you to look around and see if anyone is using as high quality materials, and control the quality from tree to tile like we do. Compare the process and the products point by point and we’re confident you’ll be buying tiles from us for years to come. Because when you build the best, confidence is a natural byproduct.

Ipe Hardwood lumber products

IPE –(Tabebuia spp.)

Common Name: | Iron Wood, Lapacho, Brazilian Walnut, or Yellow Poui |

Botanical Name: | Tabebuia spp. |

Indigenous to: | Tropical Americas (Central and South America) it is also farmed commercially. |

Modulus of Rupture: | 25,660 lbf/in2 (177.0 MPa) |

Shrinkage: | Radial: 5.1%, Tangential: 6.4%, Volumetric: .68%, T/R Ratio: 1.3 |

How is it dried: | Info coming soon |

Is it dried quickly: | No A slow kiln drying is recommended in order to reduce defects, especially with thicker boards |

Stability: | Moderately Stable |

Exterior Wood Recommendation: | Species covering the use class 5: Yes This species naturally covers the use class 5 (end-uses in marine environment or in brackish water) due to its high specific gravity and hardness. |

Fastening Method: | Nailing / screwing: good but pre-drilling is necessary Gluing: Yes (for interior only) with special techniques to reduce the oils Note: Gluing must be done with care (very dense wood). |

Ecosystem impact: | This wood species is not listed in the CITES Appendices or on the IUCN Red List of Threatened Species. However, Ipe species grow in very low densities, with mature trees only occurring once per every (3 to 10 hectares) of forest. Though uncommon, certified sources of Ipe are available. |

Toxicity and allergic reactions: | Skin irritant, headache, asthma, vision effects |

Odor: | Ipe has a very light mild scent while being worked. |

Products we manufacture using this species: | Deck Tiles, Decking, Rainscreen, Dimensional lumber |

Other common uses: | Cabinetwork (high class furniture) Sliced veneer Furniture or furniture components Sleepers Bridges (parts in contact with water or ground) Industrial or heavy flooring Ship building (planking and deck) Poles Stakes Hydraulic works (fresh water) Moulding Bridges (parts not in contact with water or ground) Stairs (inside) Heavy carpentry Turned goods Musical instruments Tool handles (resilient woods) Vehicle or container flooring Hydraulic works (seawater) Note: Filling is recommended to obtain a good finish. |

Susceptibility to | |

Dry Wood borers: | Durable – sapwood demarcated (risk limited to sapwood) |

Fungi: | Class 1 – very durable |

Termites: | Class D – durable |

Treatability: | Class 4 – not permeable Against dry wood borer attacks: does not require any preservative treatment |

Janka Hardness: | |

More Product Information

Jatoba – Hardwood lumber products

Jatoba –(Hymenaea Courbaril spp.)

Other common names include Brazilian Cherry, Locust, and Jut Vermehlo. Jatoba is a deep reddish brown in appearance and is available from our facilities as both FSC and Non-FSC certifications. Hard in density and somewhat hard to work, Jatoba is another wood which must be kiln-dried (KD). In traditional woodworking, Jatoba is a wood used for flooring and fine furniture. It is, however, a wood that could see more use as a decking product because of the stability and resistance to decay. We have jatoba available as decking, flooring, dimensional lumber, E4E, S4S, RS (Rough Sawn), deck tiles, and table slabs. The live edge table slabs in this species look amazing with a light contrasting sapwood along the outside edges.

Common Name: | Jatoba, Brazilian Cherry |

Botanical Name: | Hymenaea courbaril |

Indigenous to: | Central America, southern Mexico, northern South America, and the West Indies |

Modulus of Rupture: | 22,510 lbf/in2 (155.2 MPa) |

Shrinkage: | Radial: 4.2%, Tangential: 8.0%, Volumetric: 12.1%, T/R Ratio: 1.9 |

How is it dried: | Info coming soon |

Is it dried quickly: | Normal drying time Initial air drying under cover prior to kiln drying is recommended. Risks of cracks more or less important according to specific gravity. |

Stability: | High Moderately Stable to Stable |

Exterior Wood Recommendation: | Class 3 – not in ground contact, outside |

Fastening Method: | Nailing / screwing: good but pre-drilling is necessary Gluing: Yes (for interior only) Note: Gluing must be done with care (very dense wood). |

Ecosystem impact: | This wood species is not listed in the CITES Appendices, and is reported by the IUCN as being a species of least concern. |

Toxicity and allergic reactions: | Although severe reactions are quite uncommon, Jatoba has been reported to cause skin irritation. |

Odor: | No distinguishable odor |

Products we manufacture using this species: | Info coming soon |

Other common uses: | Cabinetwork (high class furniture) Furniture or furniture components Sliced veneer Industrial or heavy flooring Flooring Stairs (inside) Wood frame house Exterior joinery Exterior panelling Interior panelling Tool handles (resilient woods) Turned goods Ship building (ribs) Vehicle or container flooring Musical instruments Arched goods Wood-ware Sculpture Moulding Cooperage |

Susceptibility to | |

Dry Wood borers: | Durable – sapwood demarcated (risk limited to sapwood) |

Fungi: | Class 2-3 – durable to moderately durable |

Termites: | Class M – moderately durable |

Treatability: | Class 4 – not permeable |

Janka Hardness: | |

More Product Information